Traditional mixing Technology re-designed to improve the standards with single or double spiral.

Available in different configurations to suit all production needs.

Traditional mixing Technology re-designed to improve the standards with single or double spiral.

Available in different configurations to suit all production needs. -

-

Modular mixing system with single spiral available in 4 versions

(Available ONLY FOR MODEL GSE)

- With stick fixed to the mixing head.

- With rotating post fixed to the mixing bowl (“classic” Sancassiano solution)

- Without any post or stick

- With rotating (not motorized) post fixed to the mixing head (as per Sancassiano Double Force).

- With rotating (motorized) post fixed to the mixing head (as per Sancassiano Double Force).

-

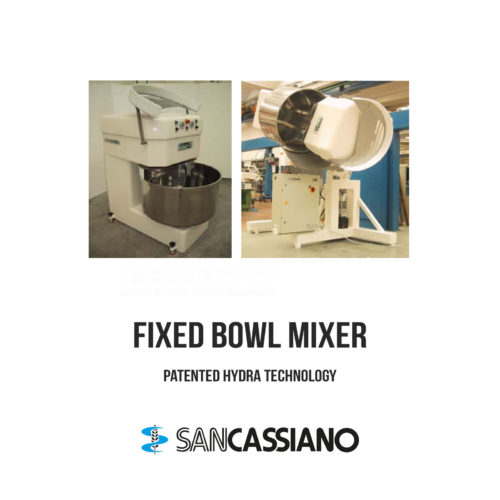

Patented dough mixer with low friction factor technology allowing:

- Reduced temperature increase during mixing (from 30 to 50% in comparison to traditional mixing technologies).

- Reduced energy consumption (from 30 to 50% in comparison to traditional mixing technologies).

- Delicate and highly efficient mixing action for a better gluten development

- Reduced use of additives and improvers for a cleaner label

- Increased dough water intake and reduced AW parameters

- Very versatile mixing action for different dough formulas and processes.

- High mixing speed thanks to twin tools technology

- Possibility of a Low cost modification to change the mixing technology (Single Spiral, Double Spiral and Revo) at any time.

-

Recently Updated:

Replaced By Bowl Tilters Now Offered with Left / Right or Backwards Tilt Please call for more information or send us an email.Hydraulic tilter model ERT

Features: Table or dough troughs tilter, hydraulically activated with tilting height of 1100 mm. Possibility to have a frontal (ERT-F)or lateral (ERT-L) discharge (specify left or right on order). Tilting action allowed through manual approval (presence of the operator required) - tilter elevated of the ground with no. 4 stainless steel feet. -

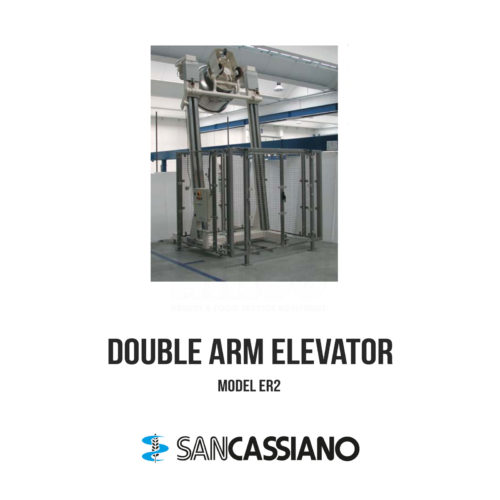

SERIES ER2

Features Oblique two arms elevator-tilter, with two screw and two synchronized motor lifting system. Patented tilting discharge. Centralized greasing and lubrication system. Tilting action allowed through manual approval (presence of the operator required *) up to 1200 mm discharge height. Automatic tilting cycle with safety cage (according to the safety regulation in force) with stainless steel grid (from 1200 mm discharge height). ) - tilter elevated of the ground with no. 4 stainless steel feet. -

Functional Features

Functional Features- Twin speed with slow speed bowl reverse

- Two timers for independent programming of slow and fast speed

- Separate push button for manual jogging of bowl during discharge

Flour = 220 lbs/100 KgDough = 350 lbs/160 KgVolume = 265 Qts/250 It -

Functional Features

Functional Features- Twin speed with slow speed bowl reverse

- Two timers for independent programming of slow and fast speed

- Separate push button for manual jogging of bowl during discharge

Flour = 109 lbs/50 KgDough = 175 lbs/80 KgVolume = 150 Qts/142 It -

SERIES F3X 40 - 200

Features: steel structure - bowl (equipped with rotating central post) and spiral mixing tool in food-grade stainless steel - 2 independent motors 2 timers - 1st and 2nd speed of the mixing tool - special executions (for "hard doughs") with strengthened motor and spiral driving with parallel axes gearbox ("head" of the industrial mixer series SE) - inversion of bowl rotation direction - jogging push button for easy discharge. Controls located on head of mixer wheels and locking devices. -

Features: Self supporting structure in painted steel - Mixing bowl and mixing tools in stainless steel - Patented kneading system by two vertical synchronized tools - Double speed kneading action controlled by two timers - Kneading tools driven by electrical motor and lubrication free parallel axes gearboxes - Bowl rotation driven by independent gearbox - Bowl lid in stainless steel completely closed - Mixer on wheels with locking devices - Jogging push button

Features: Self supporting structure in painted steel - Mixing bowl and mixing tools in stainless steel - Patented kneading system by two vertical synchronized tools - Double speed kneading action controlled by two timers - Kneading tools driven by electrical motor and lubrication free parallel axes gearboxes - Bowl rotation driven by independent gearbox - Bowl lid in stainless steel completely closed - Mixer on wheels with locking devices - Jogging push button -

Laboratory Mixer SERIES GHF/GDF/GRF

Features: Stainless steel structure - Mixing bowl and tools in stainless steel - Mixing bowl and mixing tools Independently driven by “OIL FREE driving system” to avoid dough contamination - Control of mixing tools speed by inverter for maximum flexibility - Lid in stainless steel - Side controls in separated box - Jogging push button for easier dough extraction. -

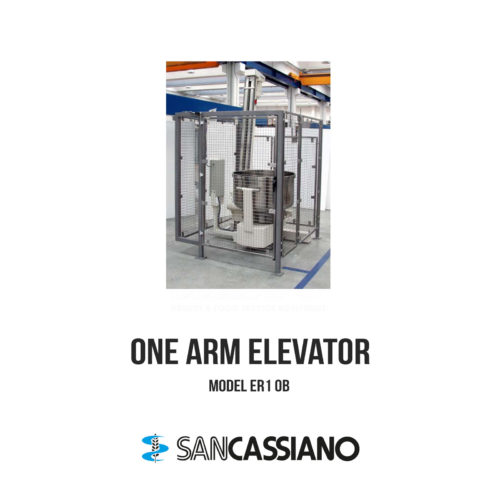

SERIES ER1-OB

Features: Oblique one arm elevator-tilter with screw lifting system, suitable up to the following bowls: CP2, PLT300-C, SE250, BTE220, FRC160, GENESI 220 (see table) Tilting action allowed through manual approval (presence of the operator required *) up to 1200 mm discharge height. Automatic tilting cycle with safety cage (according to the safety regulation in force) with stainless steel grid (from 1200 mm discharge height) ) - tilter elevated of the ground with no. 4 stainless steel feet. Single opening access door. -

Hopper Model STIA Hopper Model STM Hopper Model STL10 Hopper Model STL20 Hopper Model STL30

Hopper Model STIA Hopper Model STM Hopper Model STL10 Hopper Model STL20 Hopper Model STL30