-

Proofer/Retarder Proofer /Freezer Proofer for Racks Max pan size: 1 single rack (18”x26”) Baking quality > PID system together with the automatic computer controlled 200 step fan speed secure: • Smooth proving • Minimal dehydration • No “skinned over dough” > Slow proving at low temperature, optimizing aroma build-up and structure. > Recovery curves can handle mixed production of large and small pieces. Sanitary > No risk of sending bacteria into the chamber as in cold water systems where cold water enters directly into the chamber. > Stainless steel interior and exterior > Automatic drain for steam generator

Proofer/Retarder Proofer /Freezer Proofer for Racks Max pan size: 1 single rack (18”x26”) Baking quality > PID system together with the automatic computer controlled 200 step fan speed secure: • Smooth proving • Minimal dehydration • No “skinned over dough” > Slow proving at low temperature, optimizing aroma build-up and structure. > Recovery curves can handle mixed production of large and small pieces. Sanitary > No risk of sending bacteria into the chamber as in cold water systems where cold water enters directly into the chamber. > Stainless steel interior and exterior > Automatic drain for steam generator -

Available in different sizes with 1 to 6 rack capacity

Available in different sizes with 1 to 6 rack capacityPROOFER RETARDER

Standard Features > Programmable control with up to 7 day cycle or Easy to use Manual mode > Revent's air wash humidifier with Cool mist capacity (humidifying above 40F) -

Available in different sizes with 1 to 6 rack capacity

Available in different sizes with 1 to 6 rack capacityPROOFER RETARDER

Standard Features > Programmable control with up to 7 day cycle or Easy to use Manual mode > Refrigeration (R404 Refrigerant) with 8,600 btu capacity > Revents airwash humidifier with Cool mist capacity (humidifying above 40F) > Model 7111 and 7112 has remote mount refrigeration units as standard. The refrigeration unit is delivered in a steel frame for mounting on walls. Refrigeration lines not included. Customer to specify if it is to be installed indoors -

Proofer and Proofer/Retarder for ONE39 Round Mini oven Baking quality > PID system together with the automatic computer controlled 200 step fan speed ensure: • Smooth proving • Minimal dehydration • No “skinned over dough” > Slow proving at low temperature, optimizing aroma build-up and structure. > Recovery curves can handle mixed production of large and small pieces. Sanitary > No risk of sending bacteria into the chamber as in cold water systems where cold water enters directly into the chamber. > Floor pitched towards drain to prevent water from accumulating > Stainless steel interior and exterior > Automatic drain for steam generator

Proofer and Proofer/Retarder for ONE39 Round Mini oven Baking quality > PID system together with the automatic computer controlled 200 step fan speed ensure: • Smooth proving • Minimal dehydration • No “skinned over dough” > Slow proving at low temperature, optimizing aroma build-up and structure. > Recovery curves can handle mixed production of large and small pieces. Sanitary > No risk of sending bacteria into the chamber as in cold water systems where cold water enters directly into the chamber. > Floor pitched towards drain to prevent water from accumulating > Stainless steel interior and exterior > Automatic drain for steam generator -

SERIES BTF 50 - 160

Features: single block kneading arms made of high resistant stainless steel - stainless steel bowl - two speed arms/bowl. Lubrication free transmission by belts and gears. Manual programming by means of a control switch. -

-

Modular mixing system with single spiral available in 4 versions

(Available ONLY FOR MODEL GSE)

- With stick fixed to the mixing head.

- With rotating post fixed to the mixing bowl (“classic” Sancassiano solution)

- Without any post or stick

- With rotating (not motorized) post fixed to the mixing head (as per Sancassiano Double Force).

- With rotating (motorized) post fixed to the mixing head (as per Sancassiano Double Force).

-

Patented dough mixer with low friction factor technology allowing:

- Reduced temperature increase during mixing (from 30 to 50% in comparison to traditional mixing technologies).

- Reduced energy consumption (from 30 to 50% in comparison to traditional mixing technologies).

- Delicate and highly efficient mixing action for a better gluten development

- Reduced use of additives and improvers for a cleaner label

- Increased dough water intake and reduced AW parameters

- Very versatile mixing action for different dough formulas and processes.

- High mixing speed thanks to twin tools technology

- Possibility of a Low cost modification to change the mixing technology (Single Spiral, Double Spiral and Revo) at any time.

-

Recently Updated:

Replaced By Bowl Tilters Now Offered with Left / Right or Backwards Tilt Please call for more information or send us an email.Hydraulic tilter model ERT

Features: Table or dough troughs tilter, hydraulically activated with tilting height of 1100 mm. Possibility to have a frontal (ERT-F)or lateral (ERT-L) discharge (specify left or right on order). Tilting action allowed through manual approval (presence of the operator required) - tilter elevated of the ground with no. 4 stainless steel feet. -

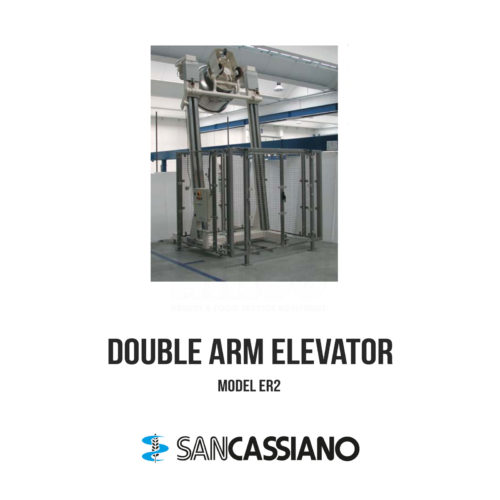

SERIES ER2

Features Oblique two arms elevator-tilter, with two screw and two synchronized motor lifting system. Patented tilting discharge. Centralized greasing and lubrication system. Tilting action allowed through manual approval (presence of the operator required *) up to 1200 mm discharge height. Automatic tilting cycle with safety cage (according to the safety regulation in force) with stainless steel grid (from 1200 mm discharge height). ) - tilter elevated of the ground with no. 4 stainless steel feet. -

Functional Features

Functional Features- Twin speed with slow speed bowl reverse

- Two timers for independent programming of slow and fast speed

- Separate push button for manual jogging of bowl during discharge

Flour = 220 lbs/100 KgDough = 350 lbs/160 KgVolume = 265 Qts/250 It -

Functional Features

Functional Features- Twin speed with slow speed bowl reverse

- Two timers for independent programming of slow and fast speed

- Separate push button for manual jogging of bowl during discharge

Flour = 109 lbs/50 KgDough = 175 lbs/80 KgVolume = 150 Qts/142 It