-

-

Humidifier EB-10 is the non-refrigerated unit. The EBK-10 is capable of retarding and cooling. Multiple units can be connected for custom proofing rooms.

Humidifier EB-10 is the non-refrigerated unit. The EBK-10 is capable of retarding and cooling. Multiple units can be connected for custom proofing rooms. -

Available in different sizes with 1 to 6 rack capacity

Available in different sizes with 1 to 6 rack capacityPROOFER RETARDER

Standard Features > Programmable control with up to 7 day cycle or Easy to use Manual mode > Revent's air wash humidifier with Cool mist capacity (humidifying above 40F) -

Hopper Model STIA Hopper Model STM Hopper Model STL10 Hopper Model STL20 Hopper Model STL30

Hopper Model STIA Hopper Model STM Hopper Model STL10 Hopper Model STL20 Hopper Model STL30 -

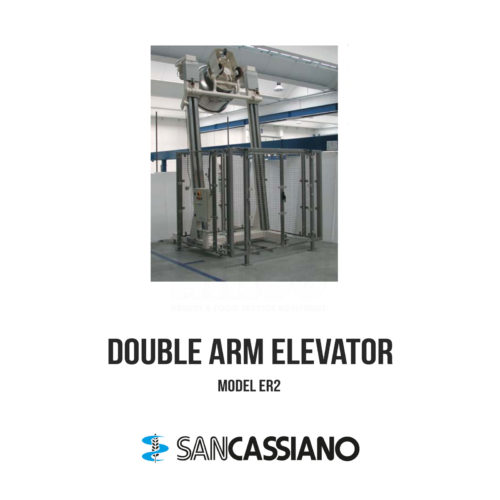

SERIES ER2

Features Oblique two arms elevator-tilter, with two screw and two synchronized motor lifting system. Patented tilting discharge. Centralized greasing and lubrication system. Tilting action allowed through manual approval (presence of the operator required *) up to 1200 mm discharge height. Automatic tilting cycle with safety cage (according to the safety regulation in force) with stainless steel grid (from 1200 mm discharge height). ) - tilter elevated of the ground with no. 4 stainless steel feet. -

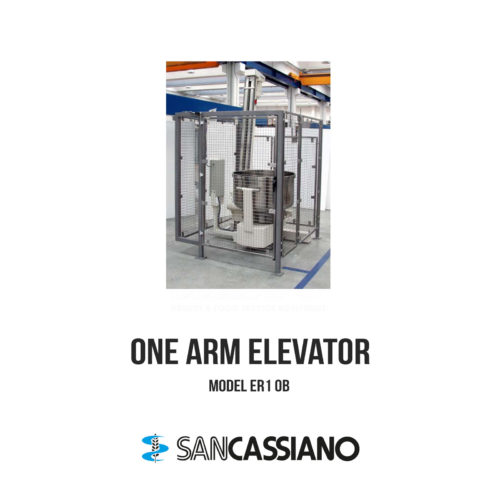

SERIES ER1-OB

Features: Oblique one arm elevator-tilter with screw lifting system, suitable up to the following bowls: CP2, PLT300-C, SE250, BTE220, FRC160, GENESI 220 (see table) Tilting action allowed through manual approval (presence of the operator required *) up to 1200 mm discharge height. Automatic tilting cycle with safety cage (according to the safety regulation in force) with stainless steel grid (from 1200 mm discharge height) ) - tilter elevated of the ground with no. 4 stainless steel feet. Single opening access door. -

Recently Updated:

Replaced By Bowl Tilters Now Offered with Left / Right or Backwards Tilt Please call for more information or send us an email.Hydraulic tilter model ERT

Features: Table or dough troughs tilter, hydraulically activated with tilting height of 1100 mm. Possibility to have a frontal (ERT-F)or lateral (ERT-L) discharge (specify left or right on order). Tilting action allowed through manual approval (presence of the operator required) - tilter elevated of the ground with no. 4 stainless steel feet. -

-

Patented dough mixer with low friction factor technology allowing:

- Reduced temperature increase during mixing (from 30 to 50% in comparison to traditional mixing technologies).

- Reduced energy consumption (from 30 to 50% in comparison to traditional mixing technologies).

- Delicate and highly efficient mixing action for a better gluten development

- Reduced use of additives and improvers for a cleaner label

- Increased dough water intake and reduced AW parameters

- Very versatile mixing action for different dough formulas and processes.

- High mixing speed thanks to twin tools technology

- Possibility of a Low cost modification to change the mixing technology (Single Spiral, Double Spiral and Revo) at any time.

-

Modular mixing system with single spiral available in 4 versions

(Available ONLY FOR MODEL GSE)

- With stick fixed to the mixing head.

- With rotating post fixed to the mixing bowl (“classic” Sancassiano solution)

- Without any post or stick

- With rotating (not motorized) post fixed to the mixing head (as per Sancassiano Double Force).

- With rotating (motorized) post fixed to the mixing head (as per Sancassiano Double Force).

-

SERIES FRC 160-500

Features: heavy steel structure - hydraulic rise and descent of head - tools’ transmission by parallel axes gearbox and belts - bowl transmission by friction wheel (two friction wheels for FRC 320 and FRC 500) - stainless steel bowl – stainless steel fork kneading arm “helicoidal” – stainless steel bowl cover completely closed, with plastic sealing ring - automatic hydraulic hooking system of bowl trolley (at the connection to the machine) and automatic descent start of the head, head descent completion by hold-to-run control - At mixing end the bowl trolley is automatically released and the head rises by hydraulic unit - operating panel separated from machine, fitted on the right side of the mixer - mixer lifted from the ground (about 85 mm) by n° 4 stainless steel feet. -

SERIES BTE 120-600

Features: Steel structure - rising head by hydraulic cylinder - bowl transmission acted by friction wheel - automatic hydraulic hooking system of bowl trolley (at the connection to the machine) and automatic descent start of the head, head descent completion by hold-to-run control – Automatic bowl release and head rise at the end of mixing with hydraulic unit and independent motorization. Stainless steel safety guard completely closed - single block kneading arms in stainless steel - bowl in stainless steel. Transmission to the kneading tools by parallel axis gearbox – self lubricating gearboxes (BTE 120 – 160) or gearboxes in oil bath (BTE 220 – 600) - control board in separate box fixed on the left side of the mixer. Different number and shape of mixing tools upon request. Recipe programmer with 5.7” touch-screen panel with the following features: