Technology Unlimited offers customized solutions for the food & process industry

TU’s slogan, “For stainless solutions,” perfectly captures their mission: providing tailored solutions for your production process. Technology Unlimited specializes in customized solutions for the food and process industries, delivering their expertise worldwide while maintaining a Dutch, down-to-earth approach.

The strength of Technology Unlimited lies in collaboration and co-development with customers. Together, they assess needs and craft the right solutions by combining extensive knowledge, decades of experience, and a commitment to innovation. Through trial and testing, they ensure their customers can grow—in efficiency and quality.

With TU, the solution is always within reach.

Technology Unlimited Services

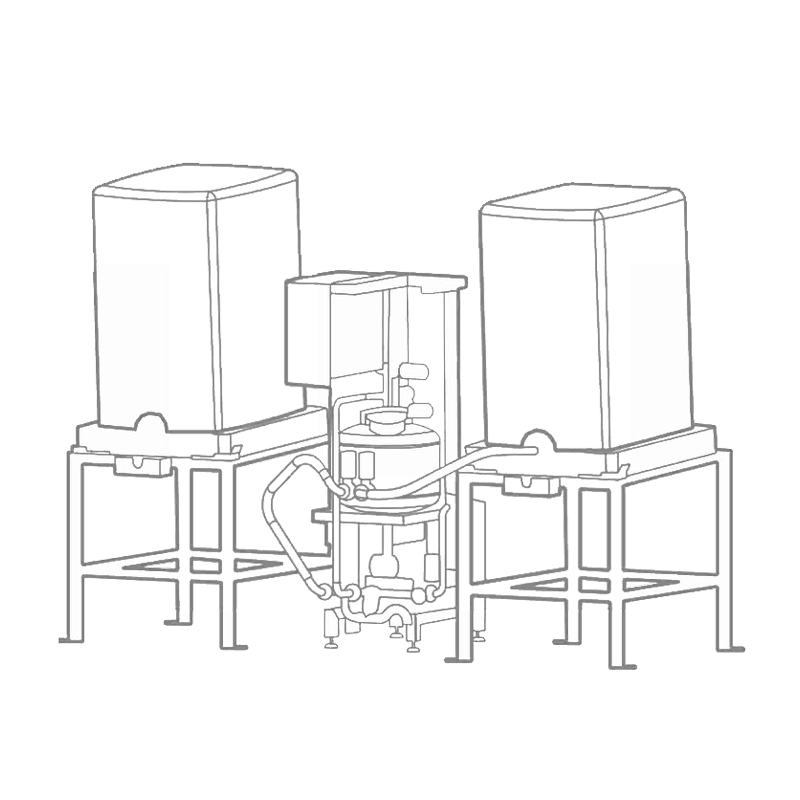

Dosing Technology

Dosing technology is a profession in itself. A profession that Technology Unlimited understands. Achieve higher yield on production? Let us automatically dose the liquids and dry products.

Liquid Products

Liquid dosing technology is designed to meet the highest standards of hygiene and food safety. Which keeps your production process smooth and compliant.

Dry Products

Need dosage of yeast or brine, for example? We have an answer. By combining precision with efficiency.

If you are looking for advanced dosing technologies to improve your production process, we are your ideal partner.

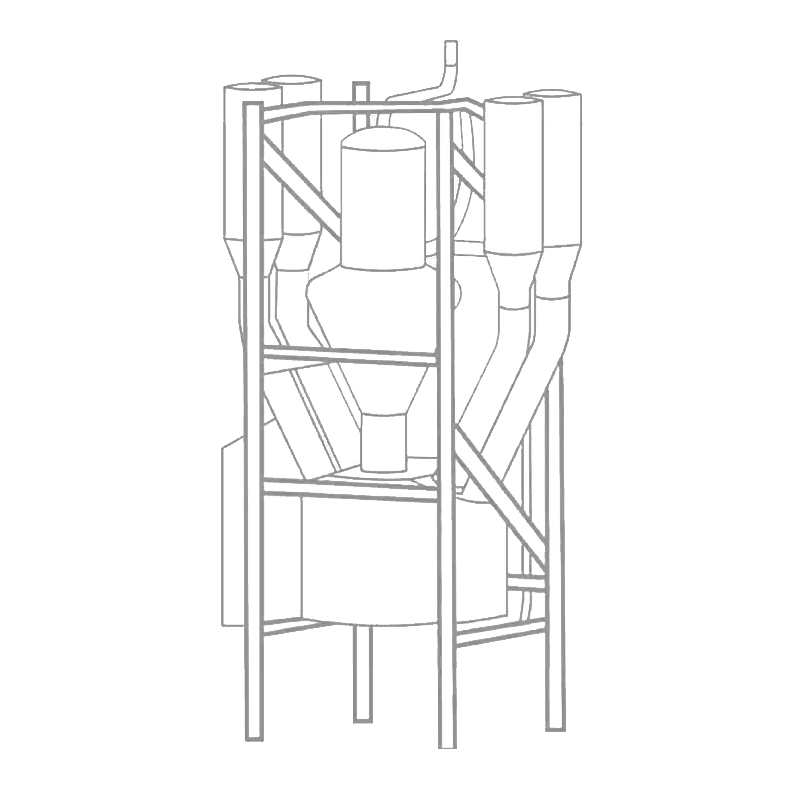

Process Technology

In the complex world of the food industry, process engineering is an invisible force. The force that makes production more efficient and ensures the quality of the end product. Technology Unlimited understands the crucial role that process engineering plays in delivering high-quality production lines for bakeries and food manufacturers.

Pump and Dosing

Air Treatment and Drying

Cooling Process

Extraction, Grinding and Melting

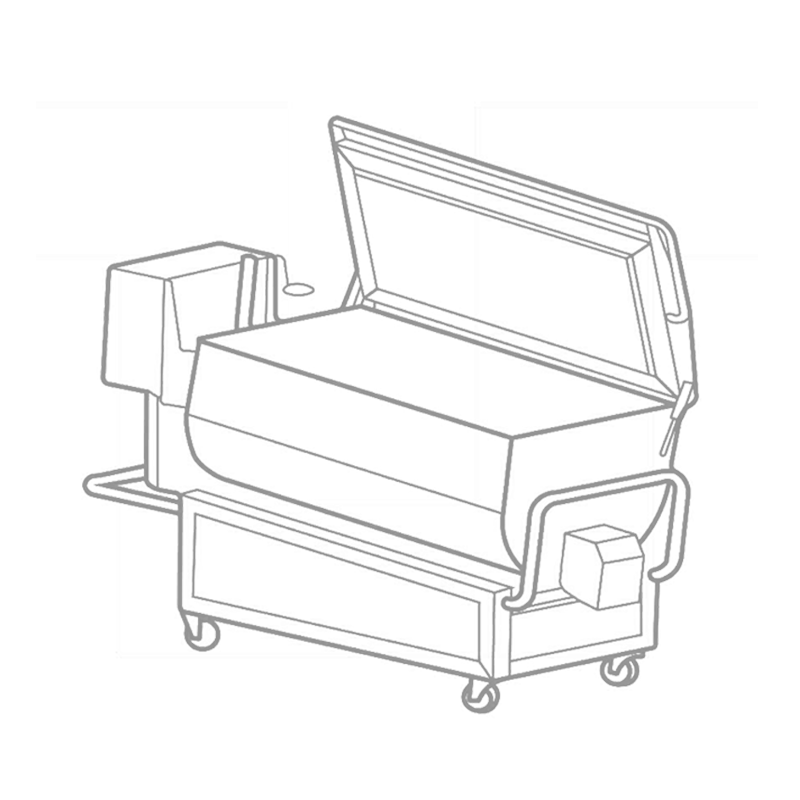

Innovation

Scrap Dough

Grill and Cooking Installation

Technology Unlimited Systems

Automation

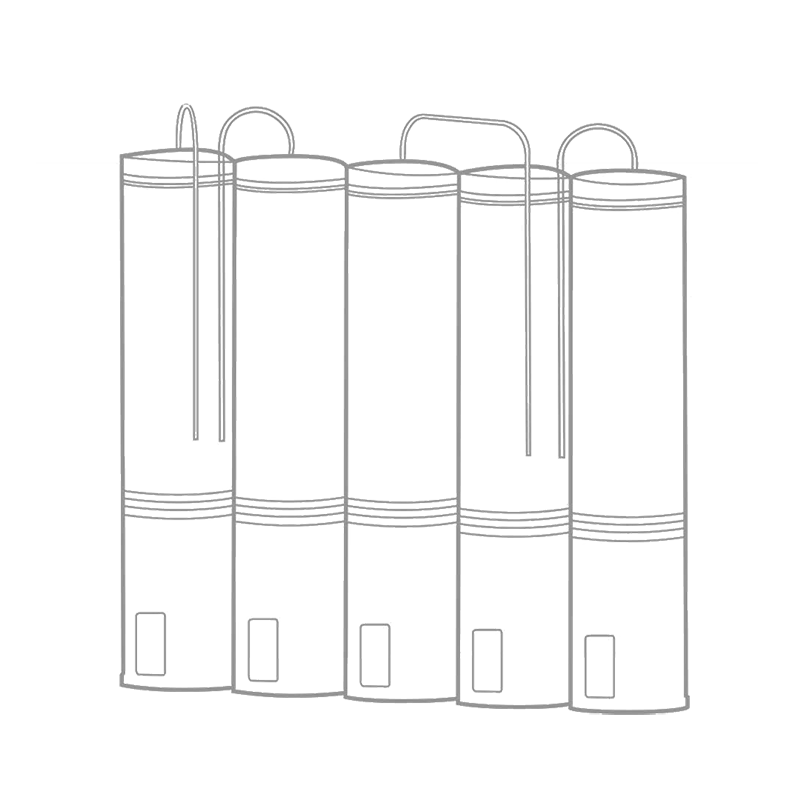

Bulk Systems

Components