Excellence in quality and reliability for over 50 years

Soren is an Italian company that has been operating in the food industry since the 1960s. The core business of the company is the design and construction of automatic systems for food industry processes.

With over 50 years of experience Soren ranks among the most prestigious brands in the industry and offers solutions of the highest level.

Soren’s technology is present in over 50 countries around the world thanks to a constant and careful update, dictated by the increasing needs of its customers, and to the progress made in designing and processing techniques.

Soren has gained a reputation for excellence in quality and reliability of its products and services and its over 400 worldwide references are a great rewarding for its restless efforts.

Soren Equipment

Process Tanks

Our worldwide distributed tank is the most advanced and reliable technology in when it comes to any mixing, cooking or cooling batch applications.

With over 50 years of experience, Soren has developed the ultimate design in order to achieve the perfect combination between homogeneous mixing and efficient heat transfer: the PCSD -15 tank.

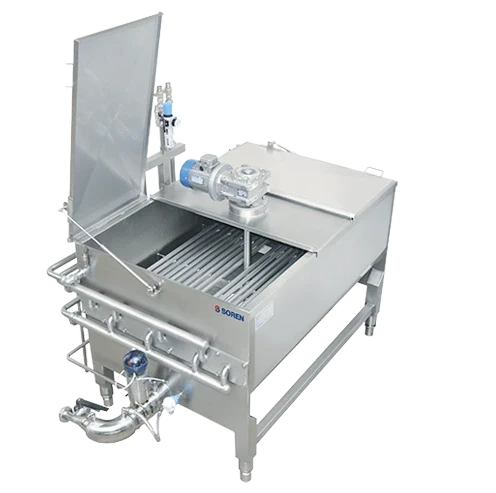

SSHE

For heating, cooling, crystallizing, pasteurizing, sterilizing.

Suited for:

- High viscosity products (e.g. filling creams, jams, gelatine, processed cheese)

- High difficulty products with large solid particulates (sauces and gravies),

- Crystallization through cooling (margarine, fat and butter),

- Efficient heat transfer through the inhibition of fouling.

Dissolvers

• Oil microdosing (Pizza, Pinsa, Focaccia, Bread)

• Depositor for muffins cakes on tray (Muffins, Cupcakes, Cakes, Brownies)

• Volumetric depositor for pastry, muffins, plum cakes, cupcakes, sponge fingers, éclairs

Melters

• Complete line for fried products (Donuts, Berliners, Long Johns)

• Decoration and injection Croissant line

• Complete line for muffins, cakes and brownies

• Pizza topping line

• Complete line for cannelloni and lasagna

Freezers

• Injector for donut holes (Donut holes)

• Vertical volumetric injector for fried products (Donuts, Berliner, Long John)

• Horizontal volumetric injector (Pastry, Buns)

• Vertical volumetric injector (Muffins, Cupcakes, Cakes, Panettone, Croissants)

• Pendulum horizontal volumetric injector for pastry (Croissants, Buns)

• Pizza base injector (Pizza, Pinsa, Focaccia, Bread)